Vehicle Load Security

Every year, within the Road Freight industry, objects which fall on to people from vehicles, cause deaths and serious injury.

Many of these incidents are as a result of poor load security (restraint) on goods vehicles being loaded/unloaded in the workplace or at drop off destinations.

Some simple measures can prevent many of these incidents from occurring, with the top of the list being 'common sense' e.g. there is no point in loading a heavy, or cumbersome object on top of something lighter or smaller and whilst this seems blatantly obvious, unfortunately it does happen, and far too often.

The Road Traffic Act 1988 (as amended) states that:

"A person is guilty of an offence if he uses, or causes or permits another to use, a motor vehicle or trailer on a road when:

- the condition of the motor vehicle or trailer, or its accessories or equipment, or

- the purpose for which it is used, or

- the number of passengers carried by it, or how they are carried, or

- the weight, position or distribution of its load, or how it is secured,

is such that the use of the motor vehicle or trailer involves a danger of injury to any person"

|

Preventing mishaps from occurring and the resultant injuries (or death) from the actions of poor load security is down to having the correct equipment to secure the load, whether it's inside a refrigerated trailer or on the back of a flatbed. There is no excuse for a vehicle to be poorly loaded under any circumstances. |

|

|

|

The Department for Transport produces an excellent publication entitled Safety of Loads on Vehicles - A Code of Practice, currently in its third edition. Some of the information on this page has been reproduced in part from that publication and we would recommend that a copy is downloaded and retained in all Transport Offices as an essential part of a Transport Managers toolkit. A link to this publication is available at the foot of the page.

|

General requirements for securing loads

The total load restraint system will generally consist of a combination of:

- lashings secured to anchorage points attached to the vehicle chassis, which includes cross-bearers, outriggers etc.

- bulking arrangements including headboards, bulkheads, spigots, transverse beams, shoring bars etc. which are securely attached to the vehicle

- friction between the load and the vehicle platform

There will be other factors concerning safe and secure loads, such as:

- being loaded correctly

- no heavy goods stacked on light goods

- the correct load restraint being used

- load restraint is in a fully serviceable condition etc.

In all circumstances, and on every occasion, it would be appropriate to secure the load correctly to ensure nothing moves from within a box or curtain sided vehicle body, or on an open flat-bed that has been securely roped and sheeted. Benefits accrued from all, and any, of the restraints used, should be regarded as right and proper.

All curtain-siders will normally require additional internal restraints.

Loads that are carried on step-frame trailers or beavertail rigid vehicles that are the subject of being ‘tied’ to the trailer or vehicle bed, should be restrained by means such as:

- webbing straps

- chains, or being,

- roped and sheeted

The final method of restraint, such as chains, should always be checked periodically, as the movement of the vehicle and/or condition of today’s road surfaces can impact upon the security of the restraint and therefore must be checked at periodic intervals during the duration of the journey.

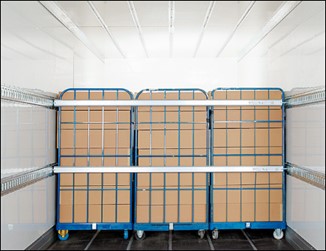

Image courtesy of Pallet Track Logistics

Given the wide diversity of general loads, it is not possible to suggest loading methods for all the types of load likely to be encountered. However, the basic precautions outlined above will always be applicable.

Vehicles equipped with headboards, tailboards or sideboards, or van bodies will provide some restraint, however, additional load restraint MUST be used in all cases as detailed below.

Additional load restraint will be required under any of the following conditions:

- If there is a risk that the load may break through the walls, sideboards or tailboard of the vehicle

- When the load is higher than the headboard, sideboards or tailboard of the vehicle

- If the load is liable to be damaged should it move during transit

- If there is a risk of the load being blown off, or bouncing out of the vehicle

Loading Arrangements on Vehicles

Two essential requirements must be satisfied when loading vehicles. These are that the load must be distributed so that:

- the maximum permitted gross vehicle weight and axle weights are not exceeded, and

- the load centre of gravity is kept as low as possible to achieve maximum stability when the vehicle is braked, or accelerated or changes direction.

For maximum stability, the items comprising of the total load should be evenly spread to achieve minimum height and be arranged to form a uniform whole so that no excessive stress is applied to whatever restraining devices are used. Where a part of the load is to be picked up or removed during the course of a journey the effect on gross vehicle weight, individual axle weights and the securing and stability of the load then being carried must be considered during the initial loading and subsequent unloading.

For example, removing a part of the load from behind the rear axle of a vehicle or trailer will reduce the gross vehicle weight, but it will increase the weight on the front axles and may cause individual axles to exceed their plated weights.

|

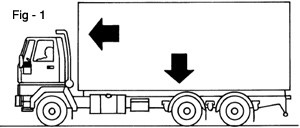

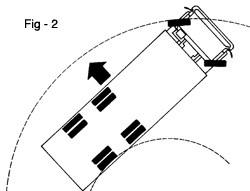

When a vehicle changes direction such as cornering on roundabouts, overtaking etc. friction is not enough to stop unsecured cargo from moving. (See Figs 1 and 2) It is wrong to assume that the weight of the load will keep it in position. |

|

|

|

In fact, heavier loads are more likely to move when the vehicle is in motion due to their kinetic energy being greater. Under heavy braking, the weight acting in a forward direction can be equal to that acting down on the vehicle. Therefore, a load that is not restrained will not be secure. |

|

Principles of Load Safety

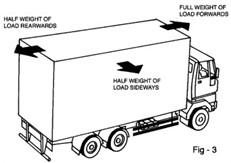

The basic principle upon which this Code of Practice is based is that the combined strength of the load restraint system must be sufficient to withstand a force not less than the total weight of the load forward, to prevent the load moving under severe braking, and half of the weight of the load backwards and sideways (see Fig 3). Vertical movement may occur but this should be overcome if the above conditions are met.

|

|

This applies to all vehicles no matter what the size, from small vans to the largest goods vehicles. These principles are based on the maximum forces that are likely to be experienced during normal road use. Greater forces may be encountered if the vehicle, for example, is involved in an accident. The principles should therefore be regarded as minimum requirements |

Restraint Equipment

Various types of equipment can be used for restraining general freight loads. These include;

- rope

- chains

- steel wire rope

- webbing

- strapping

- netting.

For the securing of loads inside van bodies and similar load containers, specially designed shoring piles used in conjunction with the appropriate securing fixtures on the vehicle are suitable. Purpose-built restraining devices should only be used for the application, and in the manner approved by their manufacturers.

Boxes

Boxes must be loaded so that they are prevented from moving in any direction:

- They should interlock if possible, and be loaded to a uniform height

- There must be at least one lashing for each row of boxes across the vehicle

- Any box which is above the general height of the load must have at least one cross lashing, more depending on weight and size.

Metals

Small relatively heavy items, such as small castings, if not palletised or caged:

- should be securely restrained and carried on sided vehicles

- the headboard, sideboards, and tailboard must be higher than the load and must be strong enough to withstand the forces generated by the vehicle’s motion.

Careful attention should be paid to points where lashings pass over corners of the load to ensure that the load is not damaged by chain links etc. or that the lashings are damaged by sharp edges. Corner protectors and sleeves should be used whenever necessary.

The friction between individual items in a load will generally be low, particularly if the metal is oiled, and should therefore be disregarded when assessing the total load restraint required.

The friction between the load and vehicle platform will also be considerably reduced if either is wet or greasy. The only exception to this rule is when concrete reinforcing weld mesh is carried. In this case, there is significant friction between the bundles of the mesh loaded on top of each other.

A large mass can be restrained more effectively than several small items and therefore whenever possible, loads should be aggregated into the largest or heaviest unit feasible. This will be controlled to some extent by the facilities available at the point of unloading.

Metal loads can take various forms but they can be broadly divided into 9 categories:

- Flat Sheet

- Long sections

- Coils

- Large units and castings

- Scrap metal

- Scrap vehicles

- Machinery and tools

- Steel for the Reinforcement of Concrete

- Combination of the above i.e. mixed loads.

Mixed Loads

When a load is composed of different items, each part of the load must be secured in a manner suitable to a load of its type. This applies mainly to cross lashings. The longitudinal lashings must be adequate for the total weight of the load, and separators must be used so that no part of the load can move forward independently. The following procedures should be followed when applicable:

- Where mixed loads involve heavy solid articles and light crushable boxes, the heavier articles should provide the base and rear part ,and the light portion be loaded on top and to the front.

- When loading different sizes of container small items should be central, with the larger items forming the outer walls of the load. Avoid as far as possible obstructions or projections beyond the vehicle sides.

- Keep irregular shaped items for the upper part of the load where it is not possible to place them centrally within the load.

- Special precautions may have to be taken when dangerous substances are included in a load. These include segregation of substances that may interact together, protection from rain and careful handling and storage to reduce the risk of damage to vulnerable containers. The packages should be loaded in such a manner as to enable the labels to be easily read.

There are many types of load other than those mentioned above including:

- sacks

- loose bricks

- timber

- pallets

- bulk liquids, powders, grain etc.

Regardless of the load type, they will all require various forms of restraint and loading in/on the vehicle and the equipment required to ensure full load security in all cases will undoubtedly vary from load to load.

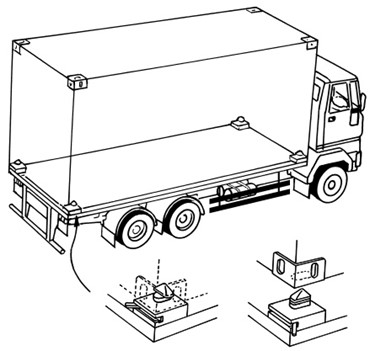

ISO Containers

The majority of containers in use are constructed to International (ISO 1496) or British (BS 3951) standards. A common feature in the construction of these containers is that specially designed corner castings are incorporated which can be used in conjunction with twist locks fitted on the vehicle, to provide a simple and positive means of restraint.

This type of container should only be carried on vehicles fitted with twist locks. Twist locks must be maintained in serviceable condition and a minimum of four used for each container carried. Provided that the twist locks are fully engaged and locked in position, the container will be adequately secured and no further restraint will be necessary.

The operator is confronted with several problems when attempting to carry ISO containers on vehicles not equipped with twist locks. Unlike normal box type loads that spread their weight over a large area, containers are designed to stand on the twist lock sockets or feet that protrude down at each corner. With heavy containers, this produces high point loading that could over-stress a normal platform floor.

Other platform vehicles may have raised or wide section side ledges which would prevent the container from resting on the platform floor. The resultant interface between the side ledges and the container feet would offer little frictional resistance making it virtually impossible to secure the container on to the vehicle safely and the practice should be avoided.

Source - Department for Transport

The following link provides guidance and further information